& SERVICES

Pact is a dynamic and robust manufacturer of packaging and other products with operations throughout Australia, New Zealand and Asia. Pact converts primarily plastic resin and also steel into packaging and related products that service customers in the food, dairy, beverage, chemical, agricultural, industrial and other sectors. Our vision is to enrich lives every day through sustainable packaging. Pact is passionate about innovation and is constantly expanding its diverse product portfolio across a variety of packaging and product substrates and expertise. The objective is to deliver customers the best possible packaging, co-manufacturing and supply chain solutions.

Chilled Food,

Dairy & Beverages

Pact has a long history of delivering sustainable and innovative packaging solutions for the chilled food, dairy and beverage sectors. Our packaging solutions cater for fresh food, chilled meat, frozen food, ready meals, baked goods, dairy products, juice and bottled water, among others. This packaging can be found on supermarket shelves, in your local convenience store and in fast food outlets.

Ambient Food & Other

Household Consumables

Ambient food relates to anything that is shelf stable and for Pact includes packaging for sauces, edible oils, and preserves, pancake mix, flour, dry mixes, rice, fruit jars, and spreads. It also includes popular household consumer products from personal care and health to the cleaning and laundry categories. You will find our household consumer products in supermarkets, pharmacies, health and beauty shops and your local hardware store.

Industrial Packaging

The industrial and chemical sector is expansive with highly varied packaging requirements that demand durability, reliability, safety and easy transit and storage. We provide packaging solutions for agricultural chemicals, surface coatings, lubricants and other petroleum products ranging from large bulk sizes to very small handheld packaging.

& Infrastructure

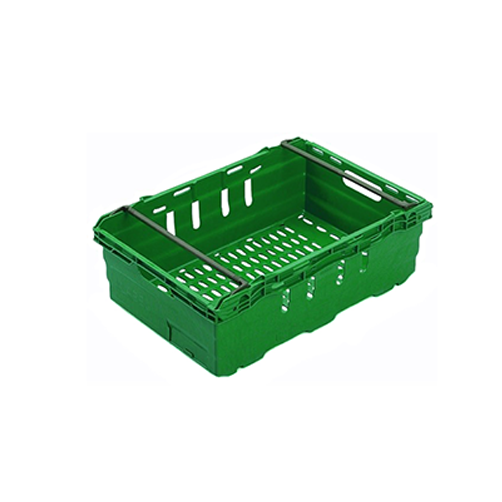

Pact’s materials handling solutions are focussed on the transportation and storage of products using pallets, crates

and other containers. We assist customers in reducing their supply chain costs through improved storage

efficiency, lower store replenishment costs and freight cost reduction. Our infrastructure solutions are focussed

on the telecommunications, gas and electrical industries, as well as major road and rail infrastructure projects

providing products, including communication pits, hazard prevention products, noise walls, industrial tanks

and more.

Pact’s diverse capabilities across packaging and product substrate

have recently been extended through the acquisitions of three

Contract Manufacturing businesses; Jalco, Australian

Pharmaceutical Manufactures (APM) and Pascoe’s.

Jalco

Jalco is Australia’s premier supplier of outsourced manufacturing and filling for the non-food FMCG sector. Jalco operates across 5 divisions;

- Home Care: manufacturer of laundry, cleaning and other household products

- Personal Care: manufacturer of facial, body and hair care products and cosmetics

- Automotive: manufacturer of automotive and industrial fluids and car care products

- Promotional Packaging: provider of specialised packaging services for special events and promotional applications

- Creative Centre: focuses on new product research and formulation development

Pascoe’s

Pascoe’s is one of Australia’s largest manufacturers of aerosol and liquid based consumer products within the household and industrial chemicals category. Pascoe’s diverse product range includes cleaning, pesticides, air care, personal care and aerosol based food products. With world class facilities, Pascoe’s supply to the major supermarkets and hardware stores throughout Australia and they also own, manufacturer and distributed a large variety of branded products.

Australian Pharmaceutical

Manufactures (APM)

APM is the largest Australian owned pharmaceutical and nutraceutical manufacturing specialists. The business provides a complete manufacturing and packaging service for a range of nutraceuticals products including:

- – Vitamin supplements

- – Mineral supplements

- – Herbal remedies

- – Amino acids

- – A range of other specialised formulations

Products are manufactured in four forms including:

- – Coated tablets

- – Uncoated tablets

- – Captures (two piece)

- – Powdered products

& Services

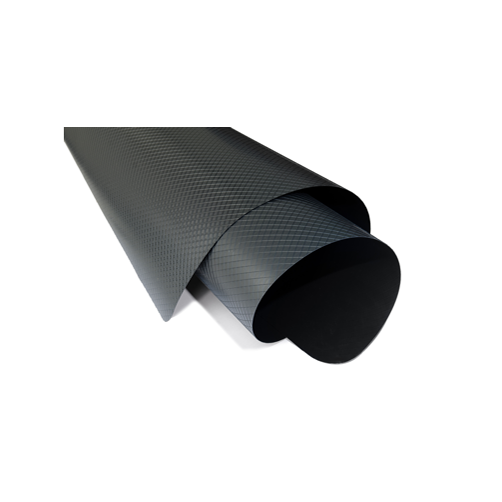

Sustainability Products and services is a growing and unique area of our business. Pact established this

division to support and complement our diverse product offering and assist our Customers meet their

sustainability commitments.

Our sustainability division is now one of Australasia’s largest processors of plastic waste. Every year, we

convert significant volumes of plastic waste into recycled plastic resin, recycled slip sheets and

underground cable covers. This area of our business focusses on the product life cycle

and closing the loop – meaning we make it, take it, re-flake it and remake it. This provides a complete and

returnable packaging solution, reducing environmental impacts and generating efficiencies for our customers.