Innovation

Pact has built a structure that unites all the

right talents, skill – sets and brains to deliver real

bottom line results to our customers.

Sites dedicated to innovation and creative support, development testing and execution.

Financial investment to creative centres supporting formulation, packaging, design and brand innovation, through to commercialisation.

Award winning staff members supporting our customers in delivering end to end solutions including product development chemists, technical design managers, lab technicians, innovation consultants and account managers.

PACT INNOVATION

Inpact Innovation is Pact’s internal innovation division. Inpact’s creative consultant’s work collaboratively with technical, engineering, design and sustainability experts to challenge conventional thinking and identify new opportunities through insight led innovation.

Whilst we have structured and proven innovation methodology, it’s not what defines us, it is simply a framework for reference. We are much more than our process. We pride ourselves on being unique because we have built a business that unites all the right talents, skill – set and brains to deliver our customers real bottom line results.

INPACT’S INNOVATION MODEL

Create

The creative process starts with category mapping to gain an insight into the competitive environments in which our customers operate. We identify the key influences of brand, product, the cosumer remains the central focus so we can better understand their behaviour and improve their experience. The insights extracted during this process guide our strategic innovation.

SOURCE

Pact searches the world to find and secure the latest technological innovations so we can deliver world – class packaging solutions and designs. Our innovation and technical teams work collaboratively to ensure each design challenge is considered from all angles. If we do not already hold the solution, we will find a way to make it happen.

ENGINEER

Concepts are transitioned from sketched illustrations on a page to full 3D rendering and tool design. Our engineers manage each step of the process, taking the project from the conceptual phase through to implementation. All aspects of making concept more environmentally sustainable are considered from light weighting via material switching and use of recycled content.

MANUFACTURE

Pact has the manufacturing capabilities and technological know – how to take Inpact’s creative concepts to the commercial world.

Case Studies

Pact Group gets A+

for a2 milk bottle redesign

On the back of a2 Milk’s nutritional credentials, they have been able to justify being positioned at a premium price point yet their packaging was almost identical to every other generic HDPE right handed handle milk bottle. A2 engaged Pact Innovation (Inpact) to run an innovation project to help the brand ‘shout and shine’ within the white mile. The objective was design a bottle to differentiate the brand on shelf, deliver value and justify the price premium in a cost down category. The redesign also had to fit the current lines throughout a2’s entire supply chain.

Helping the a2 brand shout and shine within the white mile

The redesigned bottle was created after almost 18 months of design, research and testing leading to a premium design and feel, easily distinguishable from other milk brands and packaging across Australia. The process involved researching global packaging trends and creating a design which would convey the innovation associated with being a first to market brand and product.

The redesign leverages the packaging to help a2 Milk stand out from the generic ‘white mile’ milk category. Design changes included the centre handle positioning to make it easier to pull out of the fridge, indentation on the handles for easier grip, a unique label face for maximum brand exposure and a slightly offset neck for easier pouring.

Brownes gets Smart; DuoSmart

Faced with declining market share and an impending brand refresh, Western Australian dairy giant Brownes Dairy engaged Inpact to engineer a packaging tub design that would redefine their position within the yoghurt category, deliver their unique value proposition and look stunning on shelf.

Inpact was briefed to design the right packaging family that took the brand out of the traditional and into next generation. The pack needed to fit the current filling capabilities and reflect the naturalness of the ingredients, where the brand was headed, most importantly claw back market share from the Greeks and Gourmets.

Consumer perception was “factory’ not ‘farm

A robust cross functional team from Brownes Dairy flew from Perth to Melbourne for the Innovation project. Collectively, the Inpact and Brownes Dairy team aligned on challenge, engaged a range of experts deep dived into consumers’ brains, and simulated the in-store experience.

What was discovered through the immersions was that the brand was perceived by consumers as ‘factory’ and not ‘farm’ and there was a massive opportunity for Brownes Dairy to manipulate their dairy credentials to deliver the best tasting yoghurt in the market, add warmth through their naturalness and; dial up the heritage and dairy expertise.

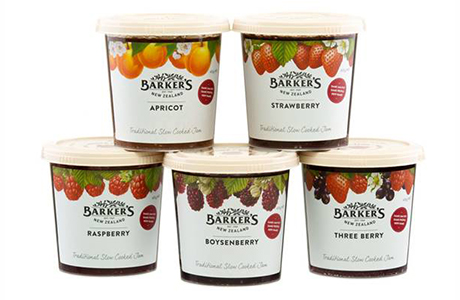

Solving Anathoth’s No. 1 Consumer Complaint

Boutique New Zealand jam and pickle manufacturer Anathoth’s number 1 consumer complaint throughout Australasia was that the lid on the jar was too hard to remove and replace; especially for elderly consumers. Inpact Innovation and plastics packaging manufacturer Tecpak collaborated to conquer!

Sourced from Superfos

Under exclusive license from global partners Superfos; Pact and Tecpak sourced the Superlock™ solution enabling Anathoth to be the first to launch the packaging technology in the Southern Hemisphere. Superlock™ is an award winning plastic packaging technology that has a user friendly, easy to open and close click-on screw lid. The package also utilizes proprietary barrier label substrate to deliver extended shelf life, particularly to oxygen sensitive products in the ambient supply chain, by substantially reducing oxygen permeation. The unique combination of a membrane seal and oxygen barrier makes oxygen transmission almost non-existent and extending the shelf life of products for up to 24 months. The container is made from Polypropylene which allows for easy recycling and is microwave, dishwasher and freezer safe.

Project Light Proof

In 2011, the $1-a-litre supermarket private-label milk war was intensifying. Competition from private-label was squeezing manufacturers’ returns if they were receiving a premium for their branded products. As margins were being crunched by aggressive price cuts and collective buying power of major supermarkets, financial pain for farmers and manufacturers was increasing. Global co-operative Fonterra approached Inpact Innovation to run an insight-led innovation project on the fresh milk category.

Keeping the light out to keep the goodness in

Independent studies showed any light strike caused degradation in milk and the loss of vitamin A within two hours of light exposure. Once damaged, fresh taste and nutritional value is impacted.

Research, prototyping and testing spanned multiple continents and involved numerous experts and taste tests. The key to the innovation was to apply triple layer technology to the packaging, ensuring the HDPE bottle was still light weight and recyclable. The inside and outside layers are opaque – the middle layer is the game changer; coloured black, it blocks out 100% of light.

Re-inventing freeway noise walls

Road traffic noise from major urban motorways is a major factor in their design – particularly in densely populated residential areas. When Southern Way was awarded the contract to construct the $759 million Peninsula Link, their Architects (ARM) were approached to consider alternate materials to standard timber, concrete and hebel products. As a result, the rotationally moulded noise abatement panels were selected. The RMP panels had to meet strict design criteria including wind loadings and noise reduction.

Plastic panels that reduce noise by absorbing and reflecting

Inpact Innovation and Pact Group subsidiary Viscount undertook extensive research, prototyping and testing to meet the numerous and rigorous specification requirements of the project and invented……The rotational moulding polyethylene (RMP) noise panels. The RMP panels are heavy-duty, rotary moulded plastic panels supported by a patented system including internal steel reinforcement. The lightweight panels are designed to reduce noise as it passes through the material by absorbing and reflecting sound through a hollow core, while the polymer surfaces are supported by galvanised steel beams and a unique mounting system. RMP panels have many other benefits in comparison to traditional noise barriers: They are lightweight, weighing in at 60kg per text panel and 900kg per geo panel, compared to concrete panels that weigh in excess of 250kg, making them quick to install and easy to transport and handle.

Despite facing a number of technical challenges, including the proper flow of resin through the handle and a number of iterations, the final design genuinely adds value for a2 Milk in that it will allow the product to be instantly recognisable in an otherwise identical market category.

The a2 Difference

Before consumer could feel the health differences by consuming a2 Milk – now that can see the difference on-pack.

“Our goal through this process was to develop a strong partnership with a market leading company that could take a creative concept into the commercial world. We have achieved this over the last 18 months with Inpact who have delivered a better packaging solution for a2 Milk that allows customers to “feel the difference”, the moment they come in contact with our product.”

Peter Nathan,Chief Executive Australia & New Zealand,

The a2 Milk Company

The pack selection to complete this transition became obvious – DuoSmart. DuoSmart gives consumers the maximum brand and promotional experience as it combines the appearance of a double sided paper cup with the functionality of plastic material. The outer paper layer provides rigidity, decorative options and insulation for the product. DuoSmart’s inner plastic layer is ideal for achieving all the necessary barrier properties. DuoSmart’s carton sleeve is derived from a renewable resource and can be comfortably removed for easy disposal and the plastic inlet is lighter in weight than normal plastic cups.

Reclaiming the title of Western Australia’s top yoghurt producer

In July 2015, Brownes Dairy launched the new DuoSmart range in parallel with new brand artwork rollout. The range consisted 15 new yoghurt recipes in 3 sizes; 170g with a printed foil and a 500g and 1kg – printed foil with clear injection moulded lid. To date, ex-factory unit sales have doubled. Brownes Dairy are now well on their way to reclaiming the title of WA’s top yoghurt producer.

In terms of branding, SuperLock™ has allowed Anathoth to enhance the quality of the decoration on products, through Injection In-Mould Labelling (IML). These labels allow enhanced graphics and images and also permit the use of transparent sections to create see-through areas to enhance the visual appeal of the contents.

Money for Jam

The consumer response from the introduction of the Superlock™ pot was overwhelming. According to Danielle Esplin, Anathoth’s Sales and Marketing Manager, “Consumer complaints dropped significantly. In fact we also received a good number of compliments about the new twist top lid and how much of an improvement it is.”

And now for the accolades…Anathoth Farm’s Sweet Chilli Relish took out the relish category at the prestigious 2015 Australian Product of the Year Awards. The awards are a culmination of Australia’s largest independent consumer survey of new products, with more than 15,000 household shoppers surveyed to determine the winners. Not only do the awards guide consumers to the best products in their markets, they also reward manufacturers for quality and innovation.

Protecting both freshness and the environment

Anchor’s LIGHT PROOF™ bottle is made from the same recyclable HDPE plastic as the old bottle. Nothing has change in terms of kerbside pick-up or drop-off and the recycled resin is being used to manufacture recycling bins used in Fonterra’s ‘Milk for Schools’ programme.

The proof is in the taste

Anchor’s LIGHT PROOF™ milk now has the same nutritional value and fresh taste across its shelf life as the day it was poured into the bottle. 73,662 New Zealanders have taken the Anchor taste test challenge with 80% preferring the light-protected milk.

The health and taste benefits from the LIGHT PROOF™ packaging innovation have acted as the cornerstone to the brand’s appeal and led to growth despite the product being priced at a premium to the competition. Anchor is the only brand that has genuinely been able to differentiate its positioning compared to other brands and private label.

- They are cost effective to produce and cost effective to install given reduced machinery needs, labour requirements and assembly time.

- They improve safety by absorbing impact in the event of a collision.

- They are environmentally friendly with a lower overall carbon footprint to manufacture than concrete panels and are 100% recyclable.

- They are corrosion and graffiti resistant.

- The panels were designed with a duel-sided surface profile

- Excellent visual appeal as the manufacturing process allows for complex designed profiles and a vast array of colours, textures and patterns options.

- UV stabilised for Australian conditions with proven UV24+ UV Stabiliser package.

The Technology Goes Global

Viscount’s patented and world-first polyethylene noise panels led to the success in winning the contract for a 27km stretch of Peninsula Link. In a 12 month period, Viscount produced over 5,000 panels (25,000 square meters).

As a result of their work on Peninsula Link, Viscount has been selected to supply some 55,000 square metres of panels to the new M5 freeway in Sydney. Potential future projects include M2 (Sydney), M8 (Sydney) and a motorway in Europe whereby the panels will be manufactured in Carrum Downs and exported to the Netherlands.