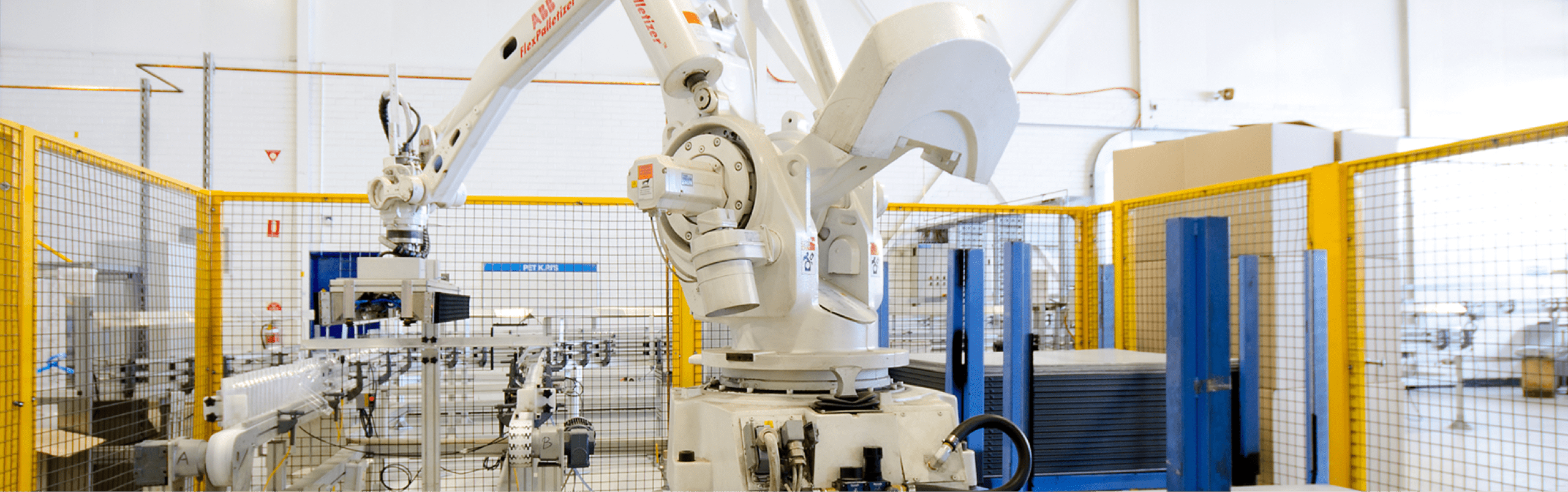

Pact has made substantial and strategic investment in a wide range of state-of-the-art equipment and manufacturing platforms.

With more than 6,600 moulds and bespoke manufacturing platforms, our technology and access to global licences enables us to vigorously compete across all categories within our chosen markets. The breadth of our technology offering and capability positions us as a supplier of choice across Australia, new Zealand and Asia for most forms of primary rigid packaging. Our high-tech manufacturing platforms enable us to deliver lower risk outcomes in terms of performance, aesthetics, sustainability and cost to our customers.

Global Licences

We have established exclusive licence partnerships and alliances with global leaders in packaging design, material science and technology.

These partnerships provide access to world-leading technology and innovations and enable us to rapidly commercialise new ideas and take these to market.

We are proud that our technology partners include:

manufacturing processes

INJECTION MOUDLING

Injection-moulded packaging includes thin wall packaging, closures,

custom mouldings and materials handling solutions. This process enables a high

degree of customisation and decoration where complex designs are required

Injection Stretch Blow Moulding

Pact offers the full range of blow moulding capabilities. This includes stretch blow moulding; the preferred process for manufacturing very high clarity PET bottles and jars and other containers.

Extrusion Blow Moulding

The extrusion blow moulding process can be used to create

diverse bottle and container shapes, sizes with varying neck openings.

Extrusion blow moulds deliver a high rate of production and are suitable for large or small production runs.

Extrusion & Thermoforming

Extrusion and thermoforming includes foam (open cell, closed cell,

in line, tandem), rigid (CPET, PP, PET, PS) and barrier / MAP (PS, PET, PP)

for low-cost, high-volume product lines.

Tubes

Tube capability includes extruded plastic tubes, plastic barrier laminate tubes

and aluminium laminate tubes. Our manufacturing processes are extremely

flexible to cater for diverse customer needs.

Rotational Moulding & Infrastructure

Rotational moulding and infrastructure spans a wide range of products

servicing a variety of industries including tanks (sanitation and water storage),

safety products, infrastructure products (telecommunication pits and covers)

and other infrastructure products like noisewalls.

Steel & Tinplate

Metal and hybrid products are predominantly supplied to the industrial

sectors and include the production of steel drums, tin plate pails and cans,

and hybrid solutions.

Contract Manufacturing

and Formulation

Pact’s Contract Manufacturing divisions includes:

– Jalco : Australia’s pre-eminent FMCG contract manufacturing service provider, a contract filler and manufacturer of personal care and household products

– APM: manufacturing nuraceuticals

– Pascoe’s: manufacturing aerosol and liquid based consumer products